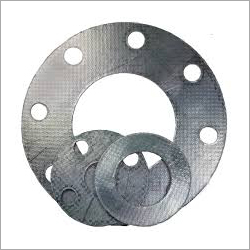

Rubber Seal

Product Details:

- Color Standard Colors: Certain colors can indicate the type of rubber or material used. For instance: Black: Commonly used for nitrile (NBR) and neoprene (CR) seals. Red: Often associated with silicone (VMQ) seals. Green: May be used for EPDM seals. Violet or Purple: Sometimes used for fluorocarbon (FKM) seals

- Medium Oil Gas Water Air

- Pressure Resistance Static vs. Dynamic: Static seals (those not in motion) have different pressure ratings compared to dynamic seals (those in motion). Ensure the seal can handle the pressure of the application

- Shape Ring Gasket

- Click to view more

Rubber Seal Price And Quantity

- 400.00 - 5000.00 INR/Unit

- 10 Unit

Rubber Seal Product Specifications

- Standard Colors: Certain colors can indicate the type of rubber or material used. For instance: Black: Commonly used for nitrile (NBR) and neoprene (CR) seals. Red: Often associated with silicone (VMQ) seals. Green: May be used for EPDM seals. Violet or Purple: Sometimes used for fluorocarbon (FKM) seals

- Oil Gas Water Air

- Ring Gasket

- Static vs. Dynamic: Static seals (those not in motion) have different pressure ratings compared to dynamic seals (those in motion). Ensure the seal can handle the pressure of the application

Rubber Seal Trade Information

- Vadodara

- Cash Advance (CA) Cash in Advance (CID) Cheque

- 500 Unit Per Month

- 7 Days

- Yes

- Free samples are available

- Box Packaging

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001 : 2015

Product Description

A rubber seal is a flexible component designed to create a tight, leak-proof barrier between two surfaces. It™s commonly used in a variety of applications to prevent the passage of liquids, gases, or contaminants, and to provide cushioning or vibration dampening. Rubber seals are made from various types of rubber, such as neoprene, EPDM, silicone, or nitrile, each offering different properties like temperature resistance, flexibility, and durability.

Here are some key aspects of rubber seals:

-

Material Composition: Rubber seals can be made from different types of rubber depending on the application's needs. For example, silicone rubber seals are excellent for high-temperature applications, while nitrile rubber seals are ideal for resisting oils and fuels.

-

Shape and Design: They come in various shapes, including O-rings, gaskets, and custom profiles, designed to fit specific applications. The shape ensures that the seal effectively conforms to the surfaces it is intended to protect.

-

Function: The primary function of a rubber seal is to prevent leaks and ensure that components remain tightly sealed. This is crucial in applications such as automotive engines, household appliances, and industrial machinery.

-

Durability: Rubber seals are designed to withstand various environmental conditions, including temperature fluctuations, UV exposure, and chemical contact. Their lifespan can vary based on the material and operating conditions.

-

Applications: They are used in many industries, including automotive (for engine gaskets), plumbing (for faucet seals), and manufacturing (for machinery components).

Send SMS

Send SMS